THIS IS A RECOMMENDED ALERT: When the OmniJet Valve Body is installed into the mounting collar, proper alignment is required with the High Pressure inlet to ensure a good seal is made with the High Pressure fitting. Jet Edge has released a self-aligning Valve Body (PN 110607) and collar set that ensures alignment and sealing on the first attempt.

Jet Edge issues Critical, Recommended and Informational updates through the use of Technical Bulletins. In order to keep your equipment safely operating at all times, it is strongly recommended that updates be implemented in a timely manner.

Click here to download a copy of the OmniJet Valve Body Alignment Tech Bulletin.

PURPOSE

Jet Edge has incorporated a self-alignment feature into the Valve Body and Mounting Collar to ensure proper alignment with the mating High Pressure fitting on the first try. Proper alignment reduces wear and the risk of leaks. To learn more about OmniJet Cutting Heads and Valve Bodies, visit our Resource Center at https://jetedgewaterjets.com/resources/ and watch our Maintenance Training Video: OmniJet III Cutting Head Rebuild.

Jet Edge has incorporated a self-alignment feature into the Valve Body and Mounting Collar to ensure proper alignment with the mating High Pressure fitting on the first try. Proper alignment reduces wear and the risk of leaks. To learn more about OmniJet Cutting Heads and Valve Bodies, visit our Resource Center at https://jetedgewaterjets.com/resources/ and watch our Maintenance Training Video: OmniJet III Cutting Head Rebuild.

SYSTEMS

The Self-Aligning Body and Collar are available for all OmniJet Cutting Heads.

DETAILS

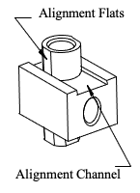

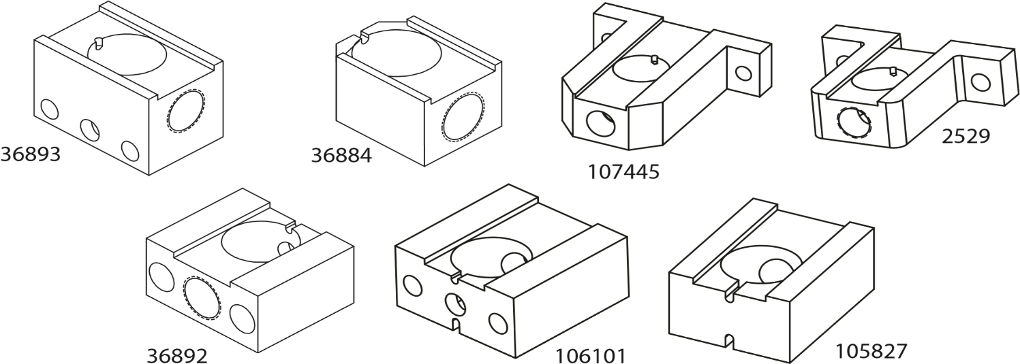

The Valve Body P/N 46627 has been replaced with the redesigned Valve Body 110607. The new Valve Body has a shoulder with flats that align the Valve Body into the newly designed collars via an alignment channel. The redesigned Valve Body is compatible with all prior collars, however, to take advantage of the alignment feature, a new collar is required.

You will find your collar P/N in the manuals that came with your equipment. The most common collars are shown in the diagram below.

Common Collars

BENEFIT

The self-alignment features are now built into the Valve Body and Collar to ensure proper alignment with the mating High Pressure fitting on the first try saving time and improving waterflow.

ORDER NOW!

Call 1-800-JET-EDGE and ask for Parts Sales to learn more about this Technical Bulletin or fill out the form on this page and someone will contact you. To order your Valve Body (P/N 110607) and Collar, contact Part Sales or order online at https://waterjetparts.jetedge.com.

FREQUENTLY ASKED QUESTIONS

HOW DO I ORDER PARTS FOR MY WATERJETS?

Jet Edge customers can order waterjet parts online anytime at http://waterjetparts.jetedge.

DO YOU SUPPLY OTHER OEM PARTS?

Yes! Jet Edge has a sister company, Choice Waterjet Parts that supplies Flow Replacement parts, OMAX Replacement Parts, KMT Replacement Parts and more! Visit them at ChoiceWaterjetParts.com or call 877-768-7893 and ask for Choice Parts.

HOW LONG WILL IT TAKE TO GET MY PARTS?

All parts orders are entered and shipped from Jet Edge the same day unless you specify a later ship date. If there are backorders you will be notified prior to shipping any other parts on the order.

CAN I SCHEDULE A SERVICE TECHNICIAN TO CHECK/REPAIR MY SYSTEM?

Jet Edge can dispatch a Service Technician to your site to perform maintenance and repair on your system or to just confirm it is performing at its peak potential. Contact our Technical Service via email at Service@JetEdge.com or call 763-497-8700 to discuss your performance goals.

DO YOU OFFER MAINTENANCE TRAINING?

Every Jet Edge water jet system includes unlimited free lifetime training at our factory headquarters. Jet Edge customers can view scheduled classes and sign up for training online at JetEdgewaterjets.com/jet-edge-training or call 763-497-8700.

Maintenance Training Videos are also available free of charge at our Resource Center https://jetedgewaterjets.com/resources/maintenance-training-videos/.

DO YOU OFFER SERVICE CONTRACTS WITH SCHEDULED SITE VISITS?

Jet Edge offers Service Contracts customized to your needs, that schedule site visits at various times during the year to perform scheduled maintenance, confirm equipment accuracy and refresh your operators on programing. Contact our Technical Service via email at Service@JetEdge.com or call 763-497-8700 to discuss your performance goals.

IS ADDITIONAL APPLICATION TRAINING AVAILABLE TO HELP MY OPERATORS IMPROVE EFFICIENCY?

At every install, Jet Edge provides training on the UHP Pump and Motion System to operators. Often, follow up training is desired to train in additional operators or to help optimize the waterjet cutting that is unique to your business. Jet Edge offers both online training and customer onsite training to ensure you are using the equipment most effectively in your shop. Contact our technical service via email at Service@JetEdge.com or call 763-497-8700 to discuss programs.