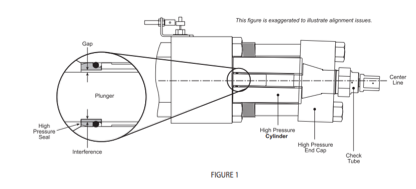

THIS IS A RECOMMENDED ALERT: When High Pressure End Caps are installed on your Jet Edge Intensifier Pump at the factory, great care is taken to align the High Pressure End Cap to the Hydraulic End Block. Failure to align the plunger and evenly torque the High Pressure End Cap causes the end cap to become misaligned. This misalignment leads to reduced High Pressure Seal life and much higher maintenance costs.

Jet Edge issues Critical, Recommended and Informational updates through the use of Technical Bulletins. In order to keep your equipment safely operating at all times, it is strongly recommended that updates be implemented in a timely manner.

Click here to download a copy of the HP End Cap Alignment Tool Tech Bulletin.

PURPOSE

The Jet Edge High Pressure End Cap Alignment Tool is now available for your maintenance team. Incorporating the use of the HP End Cap Alignment Tool ensures plunger alignment and reduces seal change time. Down time is also minimized in your shop by properly utilizing the HP End Cap Alignment Tool. Not only will you be able to align your High Pressure End Caps faster and more precisely, you can reap the benefits of longer High Pressure Seal service life that keeps your machines running and making money.

See figure 1. The Jet Edge High Pressure End Cap Alignment Tool is now available for your maintenance team.

SYSTEMS

The HP End Cap Alignment Tool is designed to work on all Jet Edge Intensifier Pumps including those with round end caps, square end caps, and xP Series end caps.

DETAILS

The HP End Cap Alignment Tool Kit includes one precision CNC machined, tight tolerance HP End Cap Alignment Tool and a detailed set of instructions explaining how to use the tool for any Jet Edge Intensifier Pump.

BENEFIT

Incorporating the use of the HP End Cap Alignment Tool ensures plunger alignment and reduces seal change time. Down time is also minimized in your shop by properly utilizing the HP End Cap Alignment Tool. Not only will you be able to align your High Pressure End Caps faster and more precisely, you can reap the benefits of longer High Pressure Seal service life that keeps your machines running and making money.

ORDER NOW!

Call 1-800-JET-EDGE and ask for Parts Sales to learn more about this Technical Bulletin or fill out the form on this page and someone will contact you. To order your HP End Cap Alignment Tool, contact Part Sales or order online at https://waterjetparts.jetedge.com.

FREQUENTLY ASKED QUESTIONS

HOW DO I ORDER PARTS FOR MY WATERJETS?

Jet Edge customers can order waterjet parts online anytime at http://waterjetparts.jetedge.com or by phone M-F 7:00 a.m. to 4:30 p.m. CST at 1-800-JET-EDGE. You also may email orders into Parts@JetEdge.com or fax orders to 763-497-8702.

DO YOU SUPPLY OTHER OEM PARTS?

Yes! Jet Edge has a sister company, Choice Waterjet Parts that supplies Flow Replacement parts, OMAX Replacement Parts, KMT Replacement Parts and more! Visit them at ChoiceWaterjetParts.com or call 877-768-7893 and ask for Choice Parts.

HOW LONG WILL IT TAKE TO GET MY PARTS?

All parts orders are entered and shipped from Jet Edge the same day unless you specify a later ship date. If there are backorders you will be notified prior to shipping any other parts on the order.

CAN I SCHEDULE A SERVICE TECHNICIAN TO CHECK/REPAIR MY SYSTEM?

Jet Edge can dispatch a Service Technician to your site to perform maintenance and repair on your system or to just confirm it is performing at its peak potential. Contact our Technical Service via email at Service@JetEdge.com or call 763-497-8700 to discuss your performance goals.

DO YOU OFFER MAINTENANCE TRAINING?

Every Jet Edge water jet system includes unlimited free lifetime training at our factory headquarters. Jet Edge customers can view scheduled classes and sign up for training online at JetEdgewaterjets.com/jet-edge-training or call 763-497-8700.

Maintenance Training Videos are also available free of charge at our Resource Center https://jetedgewaterjets.com/resources/maintenance-training-videos/.

DO YOU OFFER SERVICE CONTRACTS WITH SCHEDULED SITE VISITS?

Jet Edge offers Service Contracts customized to your needs, that schedule site visits at various times during the year to perform scheduled maintenance, confirm equipment accuracy and refresh your operators on programing. Contact our Technical Service via email at Service@JetEdge.com or call 763-497-8700 to discuss your performance goals.

IS ADDITIONAL APPLICATION TRAINING AVAILABLE TO HELP MY OPERATORS IMPROVE EFFICIENCY?

At every install, Jet Edge provides training on the UHP Pump and Motion System to operators. Often, follow up training is desired to train in additional operators or to help optimize the waterjet cutting that is unique to your business. Jet Edge offers both online training and customer onsite training to ensure you are using the equipment most effectively in your shop. Contact our technical service via email at Service@JetEdge.com or call 763-497-8700 to discuss programs.